RESTORATION 1979 – 2004

1979

No. 34059, Sir Archibald Sinclair was purchased from Woodham Brothers Ltd, South Wales for £7,250 and arrived at the Bluebell on 28th October 1979. The transport costs were met by Wiggins Teape Ltd., makers of Gateway Natural Tracing Paper.

|

|

|||

| No.34059 Loaded and ready to go at Woodam's yard Barry, South Wales | No.34059 being pulled into the running shed at Sheffield Park, Sussex. | |||

1980

The boiler clothing and glass-wool insulation has been removed. This enabled the the boiler to be inspected externally, needle-gunned and painted to protect it. A box van has been privately purchased for the group to accommodate the growing number of parts acquired and store parts removed from the locomotive.

1981

|

|

|

| 34059 on Pump House siding. | ||

An order for a complete set of cylinder cocks has been placed with Hugh Phillips Engineering. Also gauge glass columns have been cast in gunmetal using K&WVR patterns and six electric route lights have been acquired.

Practical work during 1981 was concentrated on the tender chassis, obtained from Briton Ferry Steelworks, which has been stripped down. An ex-SECR tender has been obtained and this will supply the axleboxes and one of the vacuum cylinders required.

1982

A generous donation of a Bulleid whistle has been made and one of the tree snifting valves obtained, along with a regulator handle. The valve gear and motion is now complete due to a gift of a union link, which was the only part still outstanding.

Quotations for various parts have been sought including one for a complete tender tank, which will be built away from the railway.

1983

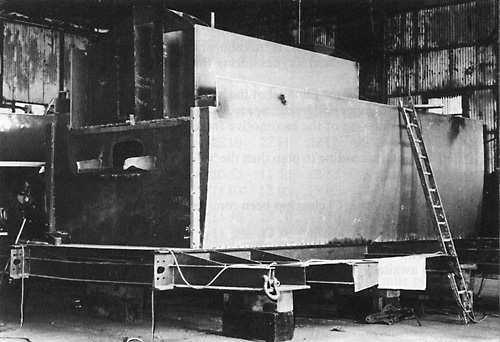

The new 5,250 gallon tank will be built by Shipyard Services of Essex who have recently completed a new tank or Taw Valley. The tender wheelset have been sent away to BR for re-profiling and the springs will be refurbished at BREL, Swindon.

The ex-Briton Ferry frame has had several sections of frame welded in where items, such as brake hangers, were cut away during its time at the steelworks.

the 5,250 gallon tender is nearing completion and the tender frames, drag-boxes and various other items have been delivered to Shipyard Services, initially so that the frames can be straightened and a quotation obtained for other work to be carried out on the frames.

|

|

| The tender tank at Shipyard Services | |

The tender tank has been delivered and members of the Battle of Britain Group have been busy grinding off excess weld as well as giving the tank two coats of primer and coating the coal space with bituminous paint. Shipyard Services have started work on the frames. The tender springs have returned from Swindon and are in the process of being painted, together with the axleboxes.

1984

The tender frame arrived on 21st April. Locker doors, hinges, catches and other minor parts for the tender have been made. On the locomotive front a pair of trailing truck bearing brasses were obtained and on order for gunmetal water connections between the locomotive and tender placed. Three crosshead oilpots have been cast.

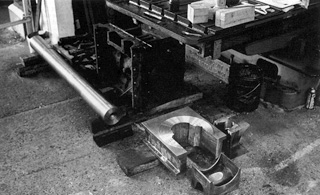

A start has been made on drilling out the rivet holes in the tender frame, a long laborious task. Hugh Phillips Engineering have supplied a pair of clack valves, a sanding valve and a vacuum ejector elbow. A vacuum cylinder form Stewarts Lane has been purchased, giving the two needed.

The tender journals have now been turned by BREL Swindon and the next job will be to re-metal the bearings ready for machining. The tender dragboxs and stretches are being riveted into place.

1985

Progress has been slow owing to the weather and other Bluebell projects taking priority. Some material for the tender brake gear is on hand, but needs machining, so is in is in the workshop queue. A Klinger shut off valve for the manifold has been purchased.

Shipyard Services has offered to complete the the rebuilding of the tender, so it has been sent to Brightlingsea along with various parts and drawings. Along with the Merchant Navy Society a bulk order was made for bogie springs for Sir Archibald Sinclair and Blackmoor Vale. A set of Bissel truck springs has also been obtained from the same source, West Bromwich Spring Co.

1986

|

|

|

| The boiler is lifted after being separated from the ashpan. | ||

A number of gunmetal castings for the lubrication system has been acquired along with front underkeeps for the bogie. The main driving underkeeps had been removed at Barry, which we have now sourced. New injectors, manufactured by Davis and Metcalfe of Romiley, Cheshire, have arrived. This was a bulk order from several Bulleid groups.

Other parts recently acquired include the steam valves for the manifold, fittings for the inside connecting rod and a set of cab window.

Work has been carried out on the boiler to release it ready for lifting. This has including the removal of the steam pipes and superheater header and releasing the cab from the frames – not easy owing to badly wasted bolts. Burning gear was required to release the smokebox from the saddle. Brake gear and other pipework has also been dismantled.

Work at Shipyard Services has continued with the completed tender tank has been but on the frames and work is progressing on the brake gear, axleboxes and bearings.

Owing to limited space at Sheffield Park the boiler could not be accommodated, but an offer from Shipyard Services to give it a home in their yard has solved the problem. The locomotive was made ready for the move from the Pump House siding and the move was made on 21st September. On Saturday 27th September the boiler was lifted and placed on the lorry ready fro its journey to Essex. The main frames will follow in due course

1987

The bogie and truck have been removed and stripped apart, needle gunned to bear metal and painted to top coat stage. Other work on the trailing truck has included dismantling the side control gear and riveting the right hand side trailing horn guide, which was found to be loose, plus repairing wasted sections on the top of the truck. The driving, bogie and trailing truck wheels have arrived back from BREL Swindon after turning and journals polished.

As there is a problem with the tender brake gear it was decided that Shipyard Services should concentrate on the main frames. The cab frame has been dispatched to O.C.S. at Dartford, who will be rebuilding it once the relevant information has been gathered.

1988

Work continues on the trailing truck, including the re-metaling of the bearings. The spring hangers were found to be badly wasted, so new ones have been ordered.

1989

The trailing truck has been completed, but it has been discovered that the bogie was twisted and the horn guides were out of alignment. The leading pair were removed, these were the worst, and taken to the workshop to be rectified and then refitted. With something square to work to the rear ones could be attended to.

The main frames have now been returned and have been painted to top coat stage. the valves and pistons have been dismantled and sent away to be re-ground also the slide bars were sent to Swindon for grinding. The weighshaft for the reverser has been but back in place after overhaul and painting and the focus of attention has turned to the steam brake cylinder and linkage.

The platform steel work sections were cut and folded by a local firm, so the team just needs to drill and fit them. As it has been decided we couldn't afford a complete boiler overhaul it has been decided that Sail and Steam would just shotblast the boiler and fabricate a new smokebox and door and deliver it back to Sheffield Park.

One of the original nameplates and crest has been purchased from the RAF museum, Hendon. The crest shows signs of damage caused in service.

1990

The re-wheeling of 34059 took place on 8th June 1990. The brake gear has being cleaned and rebushed plus the sanding gear, steam heat and vacuum pipework repaired prior to refitting. The platform plates have been painted and are now in position. The refurbished main driving wheel spring has also been fitted. New studs for the front and rear cylinder covers had been fitted after which the cylinder cladding has been put in place. The ashpan is now being fabricated.

Because of the problems with the ex Briton Ferry tender twisted frame it has been decided to order new frame plates and incorporate parts removed from the old frame, such as frame stretchers, drag boxes and horn guides.

1991

The sanding gear is complete and the 12-feed and 6 feed lubricators are in position and much of the lubrication pipework is completed. Orders have been placed for the tender brake hangers and the dragboxes.

The new tender frame plates have arrived, plus a new cast for the for the middle axlebox spring shoes. A Weslack brake adjuster for the tender has been obtained and the tank has received its first top coat.

All lubricators and associated pipework has now been assembled on the frames. Snifting valves and drain cocks have been fitted to the cylinders. New bushes have been fitted to the brake gear and the six brake hangers for the tender have arrived.

1992

Work on the new tender chassis is taking place, which is now being built virtually from scratch. Patterns and subsequent castings for the brake shaft trunnions have been made together with all the brake rods for both the steam and manual systems. Also two new drag boxes have been made. The injectors for the locomotive have been machined.

All the brake gear on the locomotive has been completed and the expansion links fitted. The copper pipework feed to the sanding gear has been completed.

The side frames for the tender are mounted on trestles in the yard and spring hangers pockets and brake hanger brackets have been rivetted in place.

1993

Following the drilling and reaming of the tender chassis the horn guides have been fitted in place and the slidebars have been fitted to the locomotive.

The tender frame assemblies were lifted onto the boiler trolley on 22nd September to make it easier to riveted it together. The new frames were then lowered onto the restored Bulleid wheelsets using the workshop overhead cranes on 17th December, followed by the tender tank a few days later.

1994

The tender lockers have been completed along with the water treatment canister and the two wooden stands for the vacuum reservoir cylinders. The conduit for the electric route indicator lamps has been fitted.

1995

The last of the tender brake gear has been fitted.

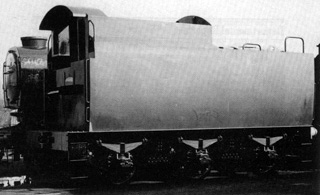

|

|

|||

| Axlebox in the workshop | The completed 5,250 gallon tender | |||

1998

All the motion work is being rebushed and cleaned in preparation for fitting.

2002

Having made a good start on the boiler repairs, the boiler has unfortunately had to be taken out of the workshop to make room for other work, However we are confidently expecting it to return soon and work to recommence on its overhaul.

|

||

| The new firebox tubeplate after the drilling of the large and small tube holes at Sheffield Park. | ||

|

|

|

| The newly cast chimney awaiting cleaning and painting. | ||

The inside connecting rod has arrived with thanks to Willie Bath of Southern Locomotives for overseeing the manufacture of the rods and for the arrangements for transportation.

Another recent delivery has been a new chimney casting. We had known for some time that all the lugs, onto which the petticoat bolts, were fractured and a new chimney was really required. The Mid Hants Railway had recently had a pattern made for a Bulleid chimney and through the good offices of Steve Humby and Clive Holiday we were able to order a casting, which has now been cleaned and painted.

|

|

|

| The boiler being lowered onto a well wagon. | ||

The main centres of work have been on finishing the inside and outside crossheads, restoring the valve spindle gland housings, bead blasting the chambers plates, valve ring packings and the garter springs. The crosshead and slide bar oil pots have been recently machined from raw castings by Derek Barlow and his next job is expected to be the valve gland bushes.

Although the boiler news is not positive, the time schedule for the overhaul of this major item is being vigorously pursued.

Spring 2003

A new steam brake casting has arrived. The outside valve gear crossheads have been assembled and all the lubricator pipe runs have been completed. It is hoped to recommence boiler work later this year and to rebore the 'middle engine' i.e. middle piston and valve.

Autumn 2003

With the imminent prospect of No. 34059 entering Sheffield Park workshop progress has been made on several fronts.

|

|

|

| No. 34059 Sir Archibald Sinclair in the running shed at Sheffield Park. | ||

The boiler has been shunted from the Woodpax siding and now stands outside the workshop where Keith Barnes has been attacking it with the needle gun and applying heat resistant paint as he goes.

The cab sheeting has been striped but as suspected, after being stored outside, needs complete replacement. After stripping the sheeting off, work is progressing on the cab frame, grinding off the rust and painting.

The reverser has been overhauled and the reverser handle, which had been cut nearly in half, has been repaired. The universal joints have had to be replaced; luckily these parts are available ‘off the shelf’ as they are still used on lorries. These items are now stored awaiting refitting.

The carrier bars for the grate have been delivered courtesy of Southern Locomotives Ltd. It is intended to fit a completely new grate.

Although we already have a 7Z Wakefield lubricator we have recently been offered a more suitable example, which is now being overhauled.

Summer 2004

With other locos needing workshop time, including No. 21C123, Blackmoor Vale, No. 34059 has not yet entered the works.

Even with this setback work has been progressing with the lubricators being fitted and work on the connecting rods taking place. While the NRM's T9 No. 120 was having its axles ultrasonically tested the opportunity was taken to have No. 34059's done at the same time and all checked out OK.

Autumn 2004

The manufacture of the boiler cladding is underway and an order for the petticoat pipe has been placed along with other Bulleid groups, which keeps the cost down. The Dartford group has been hard at work restoring a connecting rod – by hand! It now looks as though it has been machined!

The 7Z lubricator has also been fitted along with the associated pipework. Parts for the ejector have been produced including the driver's release valve, vacuum limit valve, back pressure valves for the small and large ejectors, air inlet valve plus the drip and vent valves. This work was carried out by the Dartford team.

The motion has now been completed and fitted in place.

|

|

|||

| No. 34059 with the completed motion fitted | The completed Wakefield mechanical lubricators in position. | |||

Winter 2004/5

The re-boring of the piston and valve cylinders was undertaken and the middle valve gear was replaced.