RESTORATION 2008

January 2008

|

|

|

|

|

|

| |

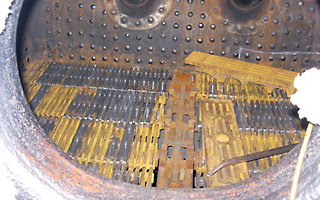

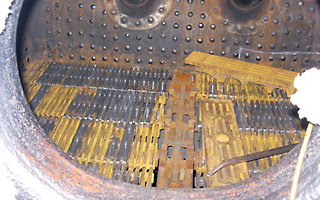

View of the new stays fitted inside the water space between the firebox and outer wrapper. |

|

Work progresses on the firebox, with the bright new stays clearly visible. |

|

|

|

|

|

|

|

| |

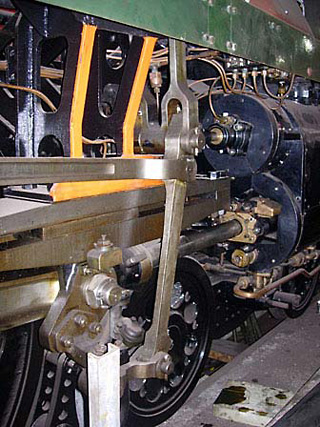

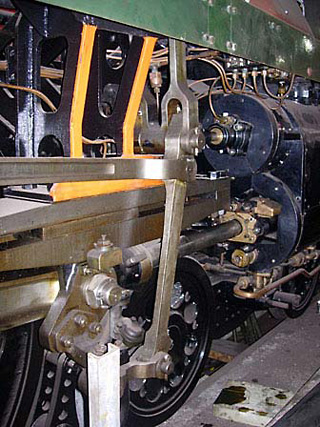

The right-hand cylinder and motion ready-to-go! |

|

The chimney petticoat casting with integral ejector exhaust being machined. |

|

March 2008

Recent work has concentrated on the boiler with the machining in house of over forty new crown stays, each nearly three feet in length, for the firebox and their insertion, knocking over and caulking. This was the last area for re-staying in the firebox. Over seven hundred and fifty new stays, both steel and monel metal, have been replaced in the firebox itself and new areas of plate have been welded in on the foundation ring areas and some of the boiler sides. In addition, all the firebox corners and much of the foundation ring have been replaced with new pressings.

All the pads on the backhead for the boiler fittings have been ground in and blanking pads have been bolted in place for the boiler hydraulic and steam tests.

|

|

|

|

|

|

| |

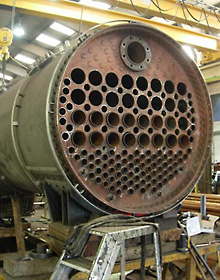

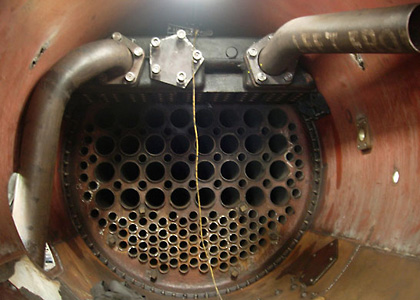

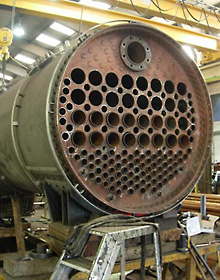

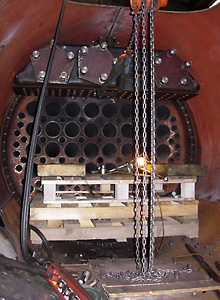

The inside of the boiler before the fitting of the main steam pipe. |

|

The new crown stays in place. |

|

The boiler was turned over and moved to the east side of the works to allow the fitting of the new crown stays. Some of the 'debris' from the boiler work has fallen into the water space in the firebox and it has been removed using the powerful washout pump. The supports for the main steam pipe in the boiler have been finished and this pipe is now in place. The main steam pipe to the superheater header has been refurbished and has been inserted in the boiler.

|

|

|

|

|

|

| |

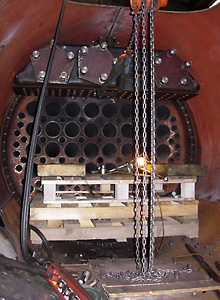

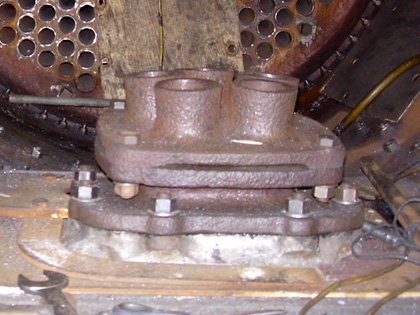

The new and old firebar carrier

side-by-side. |

|

The boiler being turned. Blackmoor Vale, in the background, is undergoing annual maintenance. |

|

The boiler is now the correct way up to enable final beading and caulking of the stays in the combustion chamber area.

The new tubes have been cleaned and painted with Apexion paint to inhibit corrosion and it is hoped that re-tubing of the boiler will start shortly. A hydraulic pressure test in the presence of the boiler inspector will be carried out after the completion of the re-tubing and the appropriate blanking off of the backhead outlets for e.g. boiler water gauges and whistle and safety valve seatings on the boiler barrel

A new centre firebar carrier, and a spare, have been fabricated for the grate as the old item was well worn!

Work on the tender has included the replacement of the middle axlebox on the driver's side and the overhaul of the two brake cylinders located at the rear of the tender. Internally, the tender tank has been cleaned and is being recoated with Bitumastic paint to inhibit corrosion.

April 2008

|

|

|

|

|

|

| |

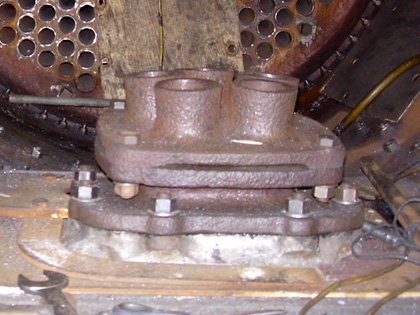

The main steam valve supplying steam to the backhead manifold in the cab bolted into place. |

|

The crinolines now adorn the boiler as it awaits tubing on 12th April 2008.

|

|

|

|

|

|

|

|

| |

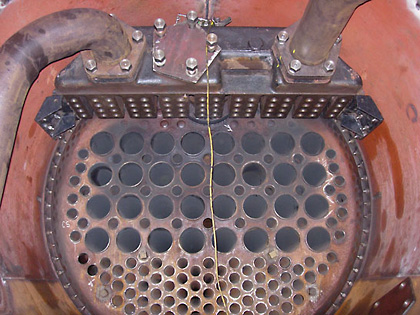

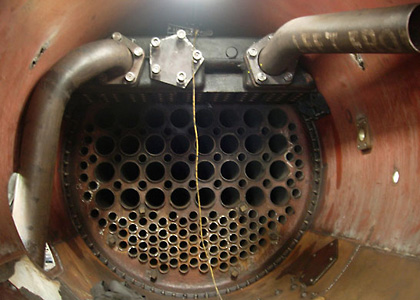

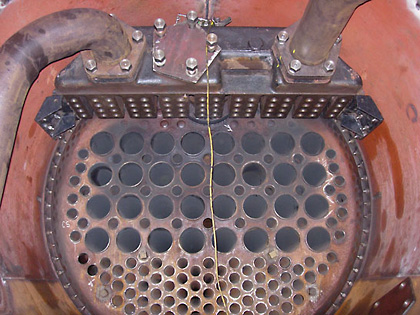

Boiler interior with flue tubes in place, main steam pipe from dome/regulator to superheater header.

|

|

The new combustion chamber platework, syphons and new tubeplate await tube fitting

|

|

|

|

|

|

|

|

| |

The boiler top with dome seating and crinolines visible.

|

|

Front tube plate with tube ends protruding. |

|

June 2008

No. 34059, Sir Archibald Sinclair had a successful boiler insurance hydraulic examination ten days ago and a successful steam test in the presence of the boiler inspector on Wednesday 4th June. Pressure was set at 100psi with very few problems. A full pressure test will be undertaken when the boiler is in the frames.

|

|

|

|

|

|

| |

Roger Cruse firing at the start of the day after the boiler had been warmed through on Tuesday.

|

|

Tony Deller, the Bulleid Society's technical adviser. |

|

|

|

|

|

|

|

| |

100 psi on the pressure gauge.

|

|

Steam via the safety valves, set at 100 psi.

|

|

The smokebox has now been attached to the boiler of No. 34059 and the combined item has been successfully, albeit temporarily, reunited with the frames.

|

|

|

| |

The boiler lifted onto the frames. |

August 2008

The work of assembling 34059 from the vast kit of parts continues.

|

|

|

|

|

|

| |

The boiler clothing and insulation is being attached to the boiler. Here the cladding around front of firebox is been adjusting.

|

|

The smokebox liner plates being drilled and bolted into place. The aperture is for the middle cylinder steam pipe.

|

|

|

|

|

|

|

|

| |

The superheater header face to main steam pipe is being refaced. |

|

The superheater header is about to be lifted into place. |

|

|

|

|

|

|

|

| |

The grate has been inserting into firebox.

|

|

The superheater elements.

|

|

The superheater element production line is underway. The photograph shows the completed superheater elements awaiting pressure testing and then fitting into the large flue tubes and attachment to the superheater header.

September 2008

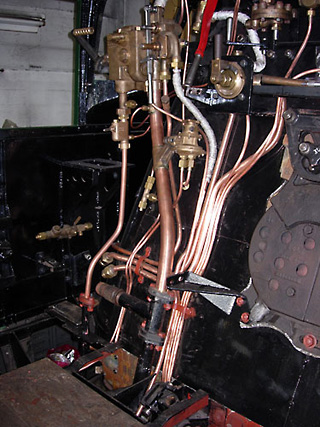

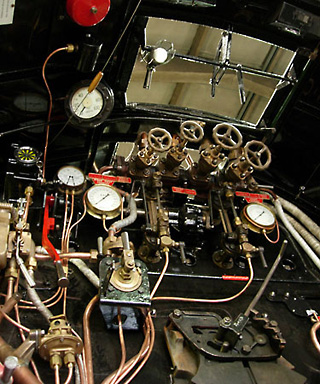

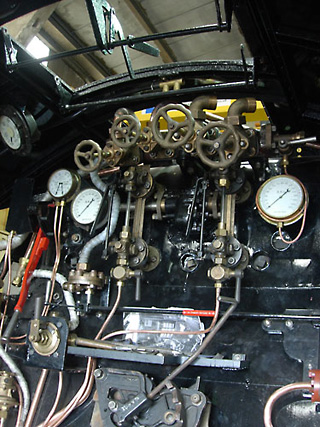

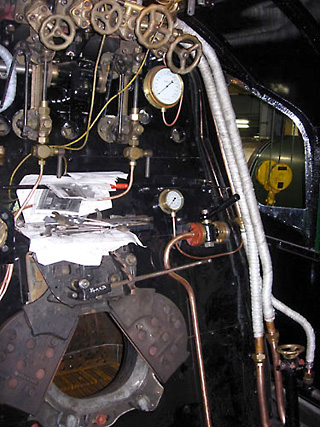

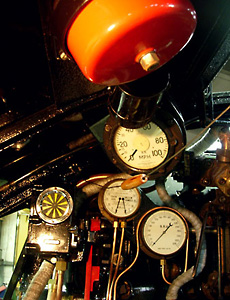

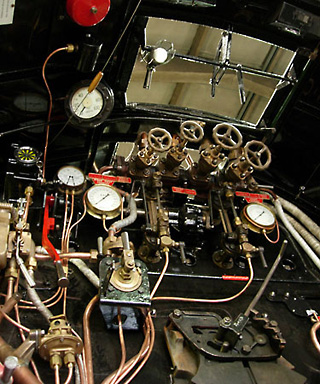

The backhead cladding painting is now complete and the fitting out of the backhead has commenced. The photograph shows the gauge glasses, most of the steam valves on the manifold, the blower fittings and the steam sanding control in place. A start will now be made on the backhead pipe runs.

The cab is being fitted out with the reverser being bolted in place, along with parts connected with the AWS, plus notices.

|

|

|

|

|

|

| |

The backhead with fittings being put in place. |

|

The inside of the cab. |

|

|

|

|

|

|

|

| |

The superheater header has been lifted and bolted to the main steam pipe. |

|

The steam pipes for the middle cylinder (left) and left-hand cylinder (right) have been fitted.

|

|

|

|

|

|

|

|

| |

View of the superheater header showing the 'apertures' for the ball ends of the superheater elements. The support brackets have also been bolted into place.

|

|

View along the right-hand running plate showing the steam pipe for the middle cylinder exiting the smokebox.

|

|

October 2008

|

|

|

|

|

|

| |

The chimney has been lifted into place on top of the smokebox.

|

|

The bottom of the chimney protruding through the smokebox awaiting final alignment and fitting of the blower ring and petticoat.

|

|

|

|

|

|

|

|

| |

The Lemaître blastpipe casting has been bolted into place.

|

|

The petticoat with integral blower ring fitted into place. |

|

|

|

|

|

|

|

| |

The main steam pipes are being fabricated from standard pipe sections.

|

|

General view of Sir Archibald taken while the adjacent road was temporary clear.

|

|

Mid-October 2008

|

|

|

|

|

|

| |

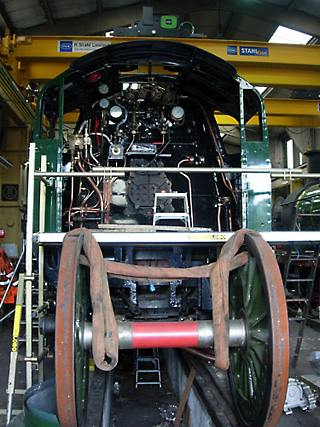

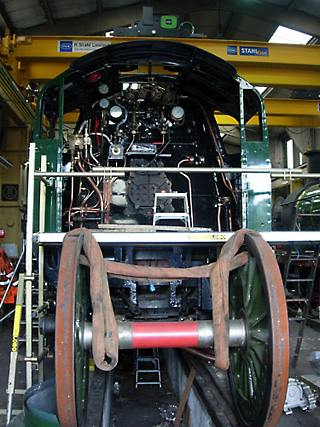

The cab has been lifted into place. The wheels in the foreground are from the S15. |

|

Work continues on fitting the boiler cladding. |

|

|

|

|

|

|

|

| |

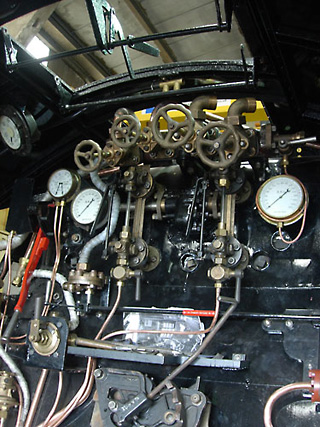

The ongoing fitting of the pipework. |

|

The steam manifold and water gauges, with above, the operating gear for the roof ventilator. |

|

November 2008

|

|

|

|

|

|

| |

With the adjacent road clear the opportunity was taken to get a complete side view of Sir Archibald Sinclair.

|

|

The fabricated right outside main steam pipe has been hydraulic tested and fitted in the smokebox. |

|

|

|

|

|

|

|

| |

The cladding being fitted around the safety valves.

|

|

Another complete side view of of Sir Archibald, this time from the rear.

|

|

Mid-November 2008

|

|

|

|

|

|

| |

The left-hand main steam pipe has ben fitted and the casing surrounding the steam pipes is being fitted. The smoke deflector, bottom left, is at hand for trial fitting. |

|

The right-hand hatch in the steam pipe cover showing the main steam pipe joint - awaiting the attachment of the snifting valve.

|

|

|

|

|

|

|

|

| |

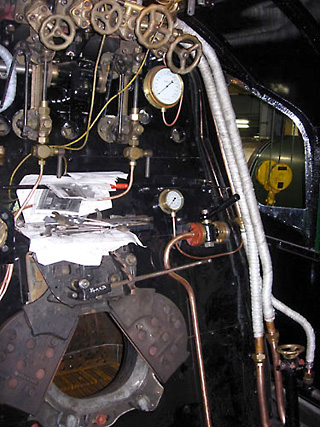

More pipework in the cab has been fitted in place. |

|

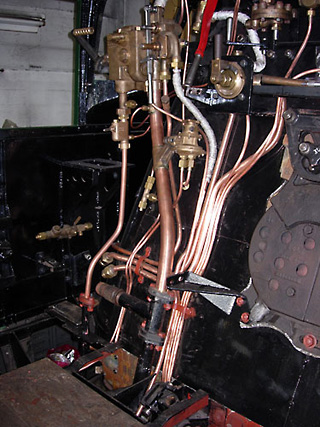

The right, fireman's side, showing the lagged pipes supplying steam to the injectors. |

|

|

|

|

|

|

|

| |

A busy workshop with No. 34059, Sir Archibald Sinclair, Maunsell U class No.3168 (in for maintenance), LBSCR E Class 32473 (under overhaul) and the boiler and wheels of Maunsell S15 No. 847. |

|

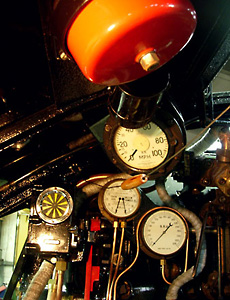

A view of the AWS cab equipment along with the speedometer, brake and boiler pressure gauges. |

|

December 2008

|

|

|

|

|

|

| |

This view of the tender was taken before the engine and tender were connected so that work can proceed on the various pipework connections between the two. |

|

The backhead is now finished with the floor plus the side windows to be fitted. |

|

|

|

|

|

|

|

| |

Left rear view showing the generator below the cab in place with its associated pipework. |

|

Pristine view of the completed backhead. How long will it stay as clean as this when it gets into service! |

|

Restoration 2009